Steel is a popular choice for industrial, commercial, and, increasingly, residential buildings due to its durability, strength, and versatility. Metal buildings can either be pre-engineered or conventional. Pre-engineered buildings are manufactured off-site and transported to the construction site for assembly, whereas conventional buildings are built on-site.

In this blog post, we’ll discuss the following six advantages of pre-engineered steel buildings over conventional buildings:

- Cost-effectiveness

- Time-efficient construction

- Design flexibility

- Structural strength

- Energy efficiency

- Reduced maintenance

Cost-Effectiveness

The components of pre-engineered buildings are designed and manufactured off-site, which reduces labor costs, construction time, and material waste. An efficiently designed pre-engineered building can be up to 30% lighter than a conventional steel building, leading to less steel usage and higher savings in structural framework. Additionally, the pre-engineered components arrive on-site expressly engineered to be assembled easily, eliminating the need for extensive on-site labor. The streamlined manufacturing process and efficient use of materials contribute to overall cost savings.

Time-Efficient Construction

Pre-engineered steel buildings can be erected faster than conventional steel buildings. Because the components are prefabricated, the foundation and structural system can be built simultaneously. Once the structural components are delivered to the construction site, the building can be put together relatively quickly because the components are the correct size and made to fit perfectly together.

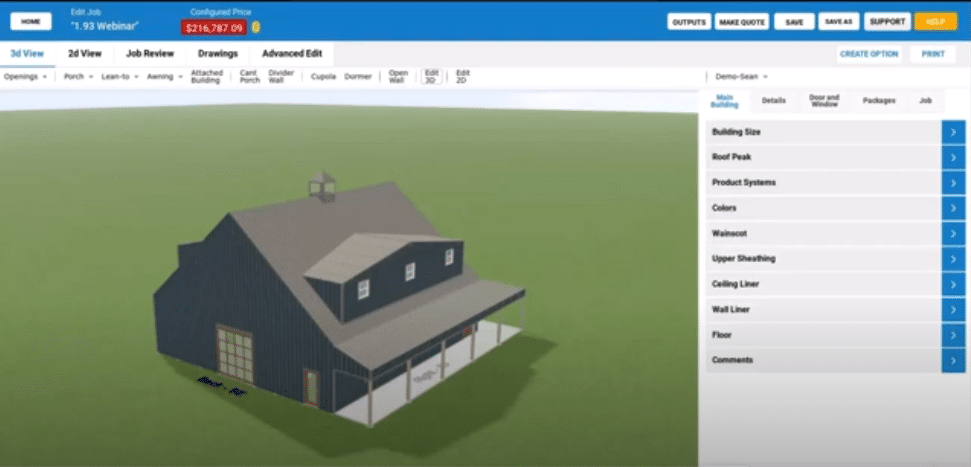

Additional time is saved when structures are designed using SmartBuild System’s metal building design software, the construction industry’s only complete design system for all-metal and pole barn structures. The web-based software generates 3D models, materials lists, pricing, proposals, and construction documents for almost any post-frame building, metal structure, or roof. More accuracy saves time!

Design Flexibility

Design flexibility is an enticing aspect of pre-engineered steel buildings. These structures can be customized to meet specific requirements, such as size, shape, and layout. The modular nature of pre-engineered building components allows for easy expansion or modification in the future. This flexibility makes them suitable for various structures, including warehouses, industrial facilities, commercial construction, sports halls, and residential buildings.

Structural Strength

Steel has a high tensile strength, making it a go-to material for builders. The components used in prefabricated steel buildings are engineered to withstand extreme weather conditions, seismic forces, and heavy loads. They are dimensionally stable, so the steel components don’t expand or contract with changes in moisture content. Additionally, the inherent strength of steel makes these structures durable and resistant to fire, pests, and decay. It’s no wonder Superman is called the man of steel!

Energy Efficiency

Energy-efficient features are easily designed into pre-engineered metal buildings. The insulation and ventilation systems can be incorporated during the manufacturing process, improving the energy performance of the building. Also, steel is the most recycled material on the planet, which aligns with sustainable building practices and environmental concerns.

Reduced Maintenance

Pre-engineered steel buildings require less maintenance than conventional buildings. Steel components are resistant to corrosion, rot, and pests, reducing the need for frequent repairs or replacements. Steel is also non-combustible, safeguarding structures from fire. When it comes to maintenance, steel structures save both time and money.

Build Your Ideal Post-Frame Structure Today

Overall, pre-engineered steel buildings offer numerous advantages over conventionally built structures, making them a popular choice for building structures.

Find an authorized SmartBuild Partner for a live design session. Watch the 3D model of your structure change in real-time with each update. Once you’re happy, the contractor prints your proposal on the spot and sends the materials order with the push of a button.

Contact us if you’re a supplier or contractor interested in becoming an authorized SmartBuild partner.