A father and son contractor team was spending 75% of their time chasing leads, yet only 15% of those deals were turning into customers. They were also frustrating their distributor who was wasting 200-man hours per year doing their bids and correcting errors. That’s when SmartBuild stepped in.

Contractor

- Cost of doing business dropped 75%

- Reduced time spent on each sale by 60%

- The deal close rate increased to 50%

- Error rate dropped to less than 5%

Distributor

- Immediately added 4 new contractors

- Increased annual sales by 10%

- Eliminated manhours spent doing takeoffs for contractors

- Reduced “ready to ship” time to 48 hours or less

The Contractor’s Story

The father and son always enjoyed building things together; it started with Lego monsters and robots. Later, the pair constructed boxcars and doghouses until finally graduating to pole barns and houses. Now the men operate a successful contractor business, they built together, after overcoming a pretty rocky start.

In the beginning, they dreamed of corps of crews breaking ground on multiple builds, but the reality was the contractors spent 75% of their time chasing jobs they rarely closed.

Inefficient Process

The contractors would get a lead and interview the building buyer’s client over the phone, trying to gather all the specs using a checklist they created in Excel. After the interview, they spent two hours doing a material takeoff, manually adding quantities and pricing to their spreadsheet to generate a bid. They hoped to get the bid to the client within 48 hours, but it was always closer to a week.

The men knew best practice was to drop off the bid to the client, but making up for lost time, often sent it via email. This process won the contractors roughly 1 out of every 7 bids – a 15% close rate.

After closing the deal, the contractors typically reviewed the bid ensuring they submitted the exact materials but often leaned on the supplier to build the final material takeoff.

The Distributor

The distributor knew that working with these contractors usually meant time spent doing bids as, the previous year, he’d helped with takeoffs for almost 50 projects. The distributor grew frustrated with the tedious process that required a constant back and forth with the contractors.

Even on jobs where the contractors did the final takeoff, hundreds of hours were spent manually entering data into the distributor’s system and translating it into internal part numbers.

Errors

Manually entering data into spreadsheets had an inherently high error rate, often resulting in the delivery of wrong window sizes or incorrect color scheme. As a precaution, the distributor routinely threw an additional $400-$500 worth of product on the quote, finding it cheaper than sending missing items via hot shot delivery.

The SmartBuild Decision

“At a recent trade show,” said the Distributor, “our people worked with our dealer using SmartBuild to generate more than 50 real-time bids for customers over just two days. This is exactly what we hoped to do with good Post Frame software.”

After learning that a construction software company created a complete design system for post frame buildings, the distributor decided to go with SmartBuild.

Downloadable Database

The team at SmartBuild worked with the distributor, downloading his entire in-house inventory database into the SmartBuild system. Because the distributor also manufactured his own metal sheathing, trim, and trusses, his SmartBuild database included his price quote and color scheme. The SmartBuild crew also created an entire part-number system, as well as standard sales contracts and bid form templates for the distributor.

Up and Running

Soon after setting up his SmartBuild database, the distributor was called for another contractor request by the father and son team.

The distributor showed the men how easy it was to use the data he’d established in his SmartBuild master account, then copied it over to the contractor’s user area, requiring little work to get up and running.

Built Before the Buyer’s Eyes

The distributor completely changed the way the contractors operated.

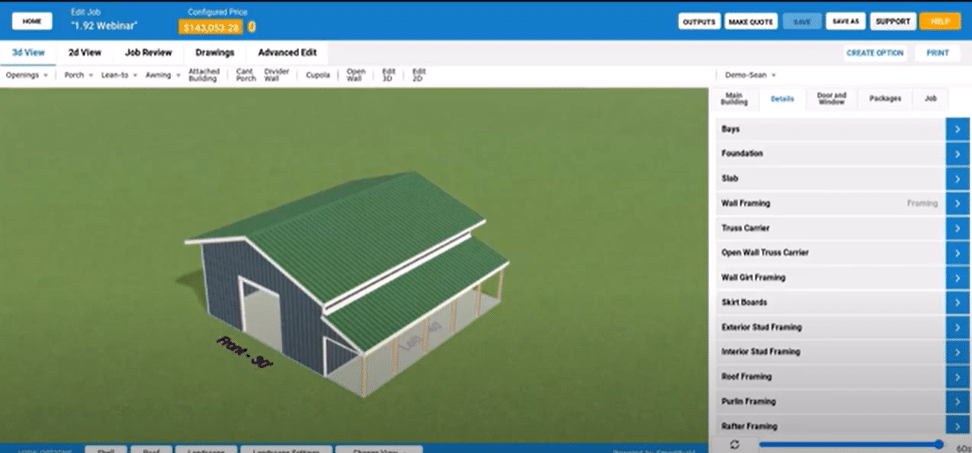

With SmartBuild, when the men got a lead, they set an appointment and worked with the buyer face-to-face. Telephone interviews and Excel spreadsheets were exchanged for a laptop on which they built the buyer’s structure, right before his eyes!

SmartBuild let the contractors work as they never could before, showing the buyer his building in 3D graphic view – with all the “what-ifs” he could imagine:

- What if we added cupolas?

- Let’s see what would happen if we didn’t have a porch…

- What would it cost to put a shed on the side?

- How about a gable roof?

- No, gambrel…

The contractors finally had a tool that bridged the gap between what the buyer was describing, and how the finished building would look. Some buyers redesigned buildings after seeing animated models, while others added more features and recalculated costs; all were happy watching their choices unfold right on the screen.

Once the buyer was happy with his building, the contractors just pushed a button and SmartBuild did the rest:

- Populated the sales contract

- Compiled the bid and order using the custom database

- Calculated the price including materials, labor, and sales tax

- Built a cut list for sheathing and trim

- Automatically generated construction drawings

- Created a description of the building

- Emailed and printed a copy for the buyer on the spot

The SmartBuild Effect

With SmartBuild, the contractors’ close-ratio went up to 50% – a 35% increase from their manual spreadsheet system.

The men now make all of their sales calls in person – in less time than it takes to do a takeoff at the office – leaving more opportunity to chase new leads.

The contractor’s new SOP – pushing a button and automatically uploading the job into the in-house system, makes the distributor’s job much easier too.

More Business All-Around

The distributor no longer does takeoffs for the contractor, nor manually enters orders into his system, saving 200-man hours per year. Furthermore, job site delivery errors have dropped exponentially.

Since setting up the father and son contractors, the distributor has used SmartBuild to close four more dealers. Those four transactions alone, have increased his annual sales by 10%.